Products

- Home

- Products

- Machine way wipers

- Aluminum machine way wiper (aluminum holder)

Machine way wipers

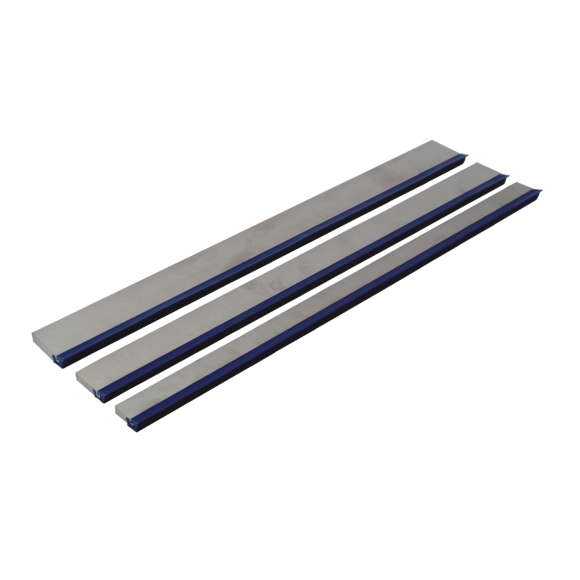

Aluminum machine way wiper (aluminum holder)

- Product Definition and Uses

- Aluminum machine wipers are cleaning and protective components for slide rails, combining aluminum alloy profiles with PU (polyurethane) scraper bodies. They are primarily used in CNC metal cutting equipment, lathes, machining centers, and various industrial equipment. Their core function is to instantly scrape away iron filings, dust, and oil films from the slide rail surface during equipment operation, preventing contaminants from entering the slide rail's moving area and causing scratches, abnormal wear, and ultimately affecting machine operation accuracy.

- The Aluminum machine wipers combined with standardized profile height ensures stable installation, fast delivery, and long-term durability, making it particularly suitable for equipment protection needs requiring rapid repair or large-scale replacement.

- In what situations is it appropriate to use aluminum machine wipers?

- In practical machine tool and production line applications, aluminum machine wipers are particularly suitable for the following scenarios:

- Rotators are frequently exposed to iron filings, dust, and cutting oil.

- A stable and continuous cleaning effect on the slideways is required.

- Fast delivery to standard specifications with minimal downtime is desired.

- High-frequency equipment requires long-term wear resistance.

- A protective solution that allows for quick replacement without complex molds.

- Compared to molded machine wiper, aluminum machine wipers offer significant advantages in delivery time, ease of maintenance, and profile flexibility.

- Structural and Material Design Specifications

- The aluminum machine wiper features a modular design, allowing for quick selection based on equipment slide rail dimensions. Its main structure and materials are as follows:

- Wiper Body Material: Polyurethane (PU)

- Excellent wear resistance and elasticity

- Good oil and chemical resistance

- Continuous temperature range: approximately -20°C to 80°C

- Base Profile: Aluminum Alloy

- Lightweight and rigid

- Easy to cut and install

- Profile Height Specifications:

- H18 to H50 (Multiple heights available)

- Standardized stock for fast delivery

- The PU scraper body maintains a stable scraping effect without damaging the slide rail surface.

- Main advantages of aluminum machine wipers

- Standard profile heights from H18 to H50 can be quickly selected based on drawings.

- Common stock available for repair and replacement needs.

- PU material provides long-term wear resistance, oil resistance, and metal shaving resistance.

- Typically, the service life is approximately 1-2 years (depending on working conditions).

- Simple structure, quick installation, and high overall cost-effectiveness.

- Selection support and customization instructions

- Aluminum machine wiper can be quickly selected and cut to fit customer equipment conditions, including:

- Profile height selection (H18~H50)

- Total wiper blade length cutting

- Mounting hole positions and fixing methods

- Operating environment (amount of metal filings, amount of oil, operating frequency)

- During the selection phase, scraping force, wear life, and slide rail protection balance will be evaluated simultaneously to ensure actual protective effect.

- Application Scope

- Aluminum machine way wiper are commonly used in:

- Traditional machine tools

- CNC lathes

- Machining centers (MC)

- Various linear guideways and industrial equipment

- Proper configuration of aluminum machine way wipers can effectively reduce the risk of guideway contamination, maintain equipment accuracy, and extend service life.

- FAQ | Common Issues with Aluminum machine way wiper

- Q1: What is the difference between aluminum machine way wiper and molded way wipers?

- A: Aluminum machine way wipers use standard aluminum alloy profiles, offering fast delivery and easy replacement; molded way wipers are suitable for applications completely customized to the shape of the slide rail.

- Q2: Is PU material suitable for scraping slide rails?

- A: Yes, PU has good wear resistance and elasticity, effectively scraping away metal filings and oil films without easily scratching the slide rail.

- Q3: Can aluminum machine way wipers be delivered quickly?

- A: Yes, most height profiles from H18 to H50 are in stock and can be quickly cut and shipped according to demand.

- Q4: What is the approximate lifespan of aluminum machine way wipers?

- A: Under typical CNC machining conditions, the lifespan is approximately 1-2 years, but the actual lifespan depends on the amount of metal filings and operating frequency.

- Q5: Which equipment are aluminum machine way wipers suitable for?

- A: Aluminum machine way wipers are particularly suitable for CNC lathes, machining centers, and industrial equipment that require stable slide rail cleaning and want quick repair and replacement.

(1).png)

(3).png)