Products

- Home

- Products

- Machine coolant tube

- Surround type machine coolant tube

Machine coolant tube

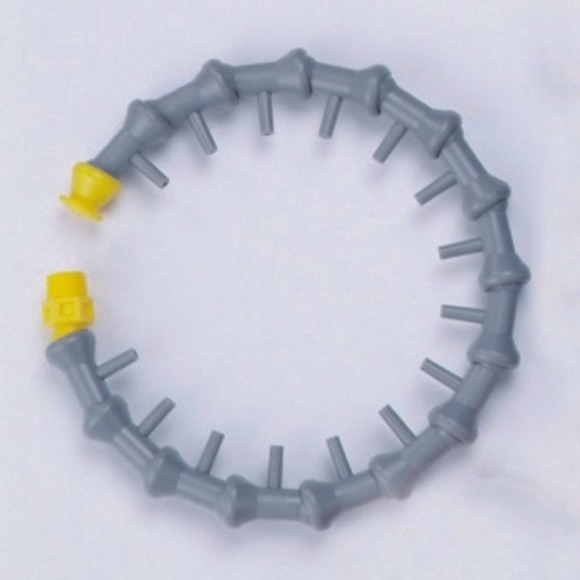

Surround type machine coolant tube

- Product Definition and Uses

- The surround type machine coolant tube is a cooling jet device specifically designed for multi-directional cooling of metal cutting tools. It is primarily used in traditional milling machines, drilling machines, CNC lathes, and CNC milling machines. Its key feature is its annular water outlet structure, which allows for simultaneous cooling of the tool and machining area from multiple directions, effectively improving the uneven cooling problem caused by single-point spraying.

- During metal cutting, the surround type machine coolant tube can quickly remove cutting heat, stabilize tool temperature, thereby extending tool life, improving machining quality, and reducing the risk of tool wear.

- When is it appropriate to use a surround type machine coolant tube?

- In actual machining environments, surround type machine coolant tubes are particularly suitable for the following applications:

- 1. Tools require 360° uniform cooling

- 2. High-speed or continuous machining with concentrated cutting heat

- 3. A single nozzle cannot fully cover the machining area

- 4. Improving tool life and machining stability is desired

- 5. Balancing cooling and chip removal effects is necessary.

- Compared to unidirectional coolant tubes, surround type machine coolant tubes offer significant advantages in cooling uniformity and heat dissipation efficiency.

- Structural and Material Design Specifications

- The surround type coolant tubes adopt a modular structure and chemical-resistant materials. Its main characteristics are as follows:

- 1. Coolant Tube Body Material:

- 1-1. Acid and alkali resistant engineering plastic

- 1-2. Suitable for machining environments containing cutting fluid and acid/alkali solutions

- 2. Cooling Structure Design:

- 2-1. Coolant enters from the inlet end.

- 2-2. Distributed evenly through multiple outlet holes on the annular structure.

- 2-3. Forms a multi-directional surround cooling water flow.

- 3. Flexible System Configuration:

- 3-1. The surround shape of the body can be changed according to requirements.

- 3-2. Switches or other piping components can be added between sections.

- 3-3. Can be fixed to any position on the equipment with a magnetic base.

- Main advantages of surround type coolant tubes

- Multi-directional surround water outlet ensures uniform cooling.

- Made of engineering plastic, it is resistant to acids, alkalis, and chemical corrosion.

- Effectively reduces tool temperature and extends tool life.

- Modular design offers high flexibility in installation and adjustment.

- Can be fitted with a magnetic base for quick and easy mounting in the desired location on the equipment.

- Selection and Usage Recommendations

- When selecting a surround type coolant tube, it is recommended to simultaneously evaluate the following conditions:

- 1. Tool diameter and machining area size

- 2. Coolant flow rate and supply pressure

- 3. Whether a flow divider or control switch is needed

- 4. Equipment mounting location and installation space

- Proper configuration can ensure maximum cooling efficiency and improve overall machining stability.

- Application Scope

- Surround type coolant tubes are commonly used in:

- 1. Traditional milling machines

- 2. Drilling machines

- 3. CNC lathes

- 4. CNC milling machines

- Through the multi-directional cooling design of the surround type collant tube, both the cutting tool and the workpiece can be cooled simultaneously, and metal chips in the machining area can be effectively removed.

- FAQ | Common Issues with Surround Type Coolant Tubes

- Q1: What is the biggest difference between a surround type coolant tube and a regular coolant tube?

- A: A surround type coolant tube can cool the tool simultaneously from multiple directions, resulting in more uniform cooling and preventing localized overheating.

- Q2: Is a surround type coolant tube suitable for high-speed machining?

- A: Yes, surround-type cooling effectively dissipates heat, making it particularly suitable for high-speed and continuous cutting.

- Q3: Can a surround type coolant tube be used in cutting fluid environments containing acids or alkalis?

- A: Yes, it is made of acid and alkali-resistant engineering plastic, suitable for various machining coolant environments.

- Q4: Can the shape of a surround type coolant tube be adjusted or accessories added?

- A: Yes, the oil spray pipe has a modular design, allowing for changes in form and the addition of switches and other components.

- Q5: Which equipment is particularly suitable for using surround type coolant tubes?

- A: Traditional milling machines, drilling machines, CNC lathes, and CNC milling machines, and other equipment requiring multi-directional tool cooling.

.png)