Products

- Home

- Products

- Machine coolant tube

- Coolant tube with high pressure buckle

Machine coolant tube

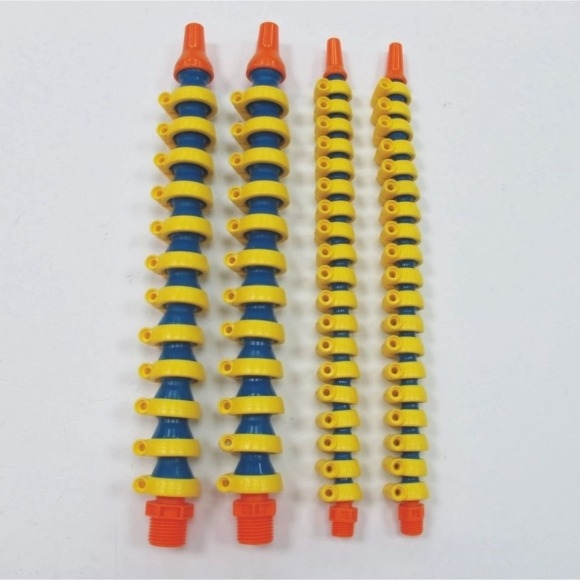

Coolant tube with high pressure buckle

- Product Definition and Application

- The coolant tube with high pressure buckle is a universal spray nozzle system specifically designed for high-pressure coolant operation. It is primarily used in metalworking equipment such as traditional machine tools, CNC lathes, CNC milling machines, machining centers, and CNC grinding machines. Its main function is to stably spray high-pressure coolant onto the cutting tool and workpiece surface during metal cutting, achieving effective cooling and chip removal.

- The coolant tube with high pressure buckle structure increases the friction between the nozzle nodes, ensuring that even under the high-pressure impact generated during coolant switching, the spray nozzle maintains its spray direction without displacement, guaranteeing precise and stable cooling.

- When is it appropriate to use a coolant tube with high pressure buckle?

- In actual machining and equipment configuration, a coolant tube with high pressure buckle are particularly suitable for the following scenarios:

- • Coolant is supplied under high pressure, and conventional fuel injectors are prone to displacement.

- • Tool position is fixed, but the cooling direction needs to be maintained for a long time.

- • High-speed cutting or high-feed machining with large chip volume.

- • Frequent coolant switching, resulting in significant instantaneous pressure shocks.

- • Desire to improve cooling system stability and machining consistency.

- Compared to fuel injectors without retaining rings, coolant tube with high pressure buckle have significant advantages in terms of resistance to displacement and positioning stability.

- Structural and Material Design Specifications

- The coolant tube with high pressure buckle hose adopts a modular universal structure and is equipped with a dedicated retainer design. Its main structure and materials are as follows:

- • Fuel Injection Hose Body Material:

- o Formosa Plastics Steel (POM): High strength, wear-resistant, and chemically resistant

- o Polypropylene (PP): Lightweight and with excellent chemical resistance

- • High-Pressure Retainer Structure:

- o The retainer enhances pressure resistance by increasing friction at the joints.

- o Secured with galvanized iron screws, providing rust and corrosion resistance.

- • Nozzle Specifications:

- o Size Options: 1/4” and 1/2”

- o Nozzle type can be selected according to processing requirements.

- • Flexible System Configuration:

- o Segmented structure, allowing for free adjustment of angle and length.

- o Can be equipped with switches, two-way valves, three-way valves, and other piping components.

- o Can be fixed to any position on the machine with a magnetic base.

- Main advantages of coolant tube with high pressure buckle

- • Suitable for high-pressure coolant applications, ensuring stable and non-displaced spray direction.

- • POM/PP material offers excellent chemical resistance.

- • High-pressure buckle are optional and highly flexible.

- • Can be quickly secured with magnetic bases, allowing for unrestricted installation locations.

- • Modular design facilitates adding or removing sections and expanding functionality.

- • Retaining rings are secured with screws for easy adjustment and maintenance.

- Customized configuration and selection support

- Coolant tube with high pressure buckle can be fully configured according to customer machining conditions, including:

- • Nozzle type and size (1/4” or 1/2”)

- • Fuel injection hose length and number of sections

- • Whether to install a high-pressure retainer

- • Whether to use a magnetic mounting base

- • Configuration of pipeline control components (switches, flow dividers)

- During the selection phase, coolant pressure, cutting conditions, and injection stability requirements will be evaluated simultaneously to ensure long-term stable operation.

- Application Scope

- Coolant tube with high pressure buckle are commonly used in:

- • Traditional machine tools

- • CNC lathes

- • CNC milling machines

- • Machining centers (MC)

- • CNC grinding machines

- Coolant tube with high pressure buckle尸尸 can significantly improve cooling spray stability, enhance machining quality, and extend tool and equipment life.

- FAQ|Common Issues with coolant tube with high pressure buckle

- Q1: What is the difference between a coolant tube with high pressure buckle and a regular coolant tube?

- A: A coolant tube with high pressure buckle has a retaining ring installed at the joint to resist the impact of high-pressure coolant switching and prevent displacement of the spray direction.

- Q2: Is a high pressure buckle always necessary?

- A: It is recommended to install a retaining ring in high-pressure cooling environments to improve the stability of the injection pipe; it is not necessary under normal pressure conditions.

- Q3: What nozzle sizes are available for the injection pipe?

- A: Nozzle sizes are available in 1/4” and 1/2” sizes, which can be selected according to cooling flow requirements.

- Q4: Can the length of the coolant tube with high pressure buckle be adjusted?

- A: Yes, the injection pipe adopts a modular segment design, and the number of sections can be increased or decreased using a special pipe wrench.

- Q5: What processing equipment is the coolant tube with high pressure buckle suitable for?

- A: Suitable for metal processing equipment requiring high-pressure coolant, such as CNC lathes, milling machines, machining centers, and grinding machines

(3).png)