Products

- Home

- Products

- Rubber strips

- Electrical cabinet rubber sealing strips (with adhensive)

Rubber strips

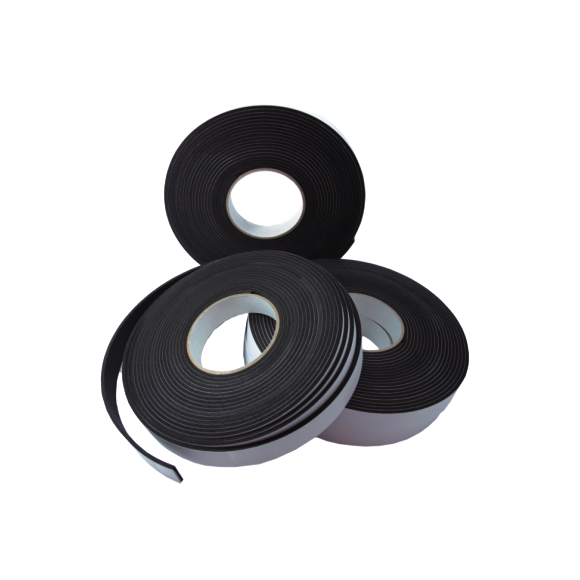

Electrical cabinet rubber sealing strips (with adhensive)

- Product Definition and Uses

- Electrical cabinet sealing strips are sealing and impact-resistant components specifically designed for the machine tool industry and various equipment electrical cabinets. They are primarily used for dustproofing, water-repellent protection, and cushioning at the joints of electrical cabinet doors and casings. Properly configured sealing strips effectively reduce the risk of external dust and moisture entering the electrical cabinet, ensuring stable operation of electrical components and extending their service life.

- Electrical cabinet sealing strips can be selected based on thickness, width, and installation dimensions, or fully customized, suitable for electrical cabinets of different specifications and structural forms.

- In what situations is it appropriate to use electrical cabinet sealing strips?

- In practical equipment and computer room applications, electrical cabinet sealing strips are particularly suitable for the following scenarios:

- 1. Electrical cabinets need to prevent dust or moisture from entering.

- 2. Cabinet doors need to provide cushioning and impact protection when closed.

- 3. Computer rooms or industrial environments have high requirements for equipment reliability.

- 4. Existing sealing strips are aging, deformed, or have lost their elasticity.

- 5. Standard-sized sealing strips cannot fully fit the cabinet structure.

- By selecting the correct sealing strip, the overall protection level of the electrical cabinet can be significantly improved.

- Structural and Material Design Specifications

- Electrical cabinet sealing strips can be customized in terms of material and size according to the usage environment and protection requirements. Their main design characteristics are as follows:

- 1. Main Materials:

- 1-1. EVA foam (general-purpose, with good sealing and cushioning effects)

- 2. Optional Special Materials (customizable upon request):

- 2-1. Silicone foam (excellent temperature and weather resistance, suitable for high-requirement environments)

- 3. Structural Characteristics:

- 3-1. The foam structure can compensate for the gap between the door panel and the cabinet body.

- 3-2. Provides stable compression rebound, improving sealing performance.

- 4. Adjustable Items:

- 4-1. Thickness and width

- 4-2. Length and cutting method

- 4-3. Material type and density

- Completely customized production is possible according to different electrical cabinet structures.

- Main advantages of electrical cabinet sealing strips

- Customized production to meet size requirements, ensuring a high degree of fit.

- The foamed structure provides both sealing and impact protection.

- Materials can be selected based on environmental conditions (general/temperature resistant).

- Effectively enhances the dust and moisture protection capabilities of the electrical cabinet.

- Suitable for long-term installation and use, offering excellent stability.

- Customized design and selection support

- Electrical cabinet sealing strips can be fully planned according to the customer's actual usage scenario, including:

- 1. Electrical cabinet dimensions and door frame structure

- 2. Required protection requirements (dustproof, waterproof, impact-resistant)

- 3. Material selection (EVA foam or silicone foam)

- 4. Thickness, width, and compression design

- 5. Installation method and ease of replacement

- During the design phase, sealing effect, rebound life, and installation stability will be evaluated simultaneously to ensure long-term reliable use.

- Application Scope

- Electrical cabinet sealing strips are commonly used in:

- 1. Electrical cabinets in the machine tool industry

- 2. Electrical cabinets for various industrial equipment

- 3. Data centers, control boxes, and distribution boxes

- 4. Cabinet equipment requiring dustproof, moisture-proof, and impact-proof protection

- Through proper electrical cabinet sealing strip design, the risk of equipment failure can be effectively reduced and the overall system stability can be improved.

- FAQ | Common Issues Regarding Electrical Cabinet Sealing Strips

- Q1: What is the main function of electrical cabinet sealing strips?

- A: The main function is to prevent dust and moisture from entering the electrical cabinet, while also providing cushioning and impact protection when the cabinet door is closed.

- Q2: What is the difference between EVA foam and silicone foam sealing strips?

- A: EVA foam is suitable for general industrial environments; silicone foam has better temperature and weather resistance, making it suitable for high-requirement applications.

- Q3: Can electrical cabinet sealing strips be completely customized in size?

- A: Yes, the thickness, width, and length of the sealing strips can all be customized according to the dimensions of the electrical cabinet.

- Q4: Do electrical cabinet sealing strips provide impact protection?

- A: Yes, the foam structure absorbs the impact when the door is closed, reducing the risk of damage to the cabinet and door panel.

- Q5: Which equipment is particularly suitable for using electrical cabinet sealing strips?

- A: Electrical cabinets for machine tools, industrial equipment control boxes, and data center cabinets are particularly suitable for using electrical cabinet sealing strips.