Products

- Home

- Products

- Rubber Covers

- Flat Type Rubber Covers

Z-axis protection

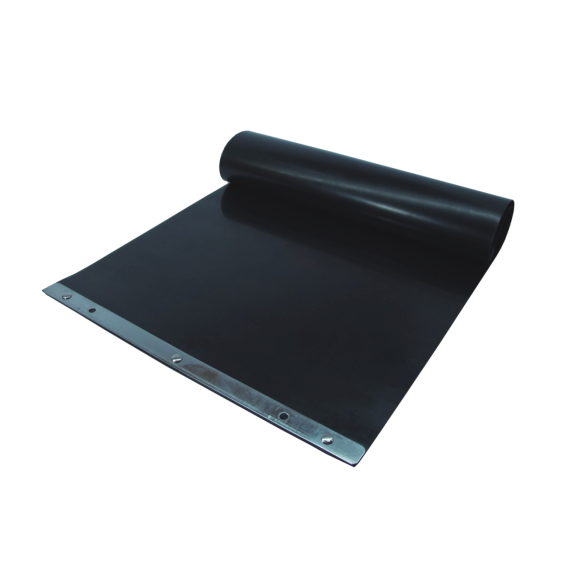

Flat Type Rubber Covers

- Product Definition and Uses

- Flat-Type Rubber Covers are protective components made of oil-resistant rubber fabric with a flat structure. They are primarily used in traditional machine tools, CNC machine tools, and various metal cutting equipment. Their main function is to effectively block metal chips from splashing during equipment operation and prevent excessive chip buildup from interfering with mechanical movement, ensuring smooth equipment operation and extending overall service life.

- The flat structure is particularly suitable for fixed protection areas or straight protective surfaces, quickly covering the path of metal chip splashes. It is a simple and effective protective solution for dealing with high chip buildup problems. The length, width, and thickness of the chip baffle can all be customized to meet specific equipment requirements.

- In what situations is it appropriate to use a flat-type rubber cover?

- In practical applications of machine tools and machining equipment, flat rubber chip guards are particularly suitable for the following conditions:

- 1. Chip spray has a clear direction and is concentrated in a specific area

- 2. The equipment protection range is a fixed or linear section

- 3. A large amount of chip accumulation is easily generated during machining

- 4. Flexible protection with oil resistance and wear resistance is required

- 5. A quick solution to chip interference problems with a simple structure is desired.

- Compared to corrugated chip guards, flat chip guards are more suitable for fixed protection surfaces and areas with high chip accumulation.

- Structural and Material Design Specifications

- Rubber flat chip guards for equipment can be customized according to actual working conditions. Their structure and material characteristics are as follows:

- 1. Chip Guard Body: Oil-resistant rubber fabric of specified thickness

- 2. Internal Structure (Optional):

- 2-1. Woven Structure (improves tensile strength and durability)

- 2-2. Unwoven Structure (more flexible, suitable for light load protection)

- 3. Fixing Method:

- 3-1. Combined with metal fixing edge (corrosion-resistant material)

- 4. Common Thickness Specifications:

- 4-1. 1.0 mm

- 4-2. 1.5 mm

- 4-3. 2.0 mm

- 4-4. 3.0 mm Capable of withstanding large amounts of iron filings splashing or accumulating, but not recommended for use in environments with excessively high iron filings temperatures.

- Main advantages of flat-type rubber cover

- Oil-resistant, suitable for metal cutting environments. Simple planar structure provides direct and stable protection. Dimensions (length, width, thickness) are fully customizable. Optional mesh overlay structure enhances tensile strength and service life. Particularly suitable for equipment areas with concentrated metal shavings or prone to shavings accumulation.

- Customized design and manufacturing capabilities

- Flat-Type Rubber Cover for equipment can be fully customized to meet the specific requirements of the customer's equipment, including:

- 1. Chip guard length, width, and thickness

- 2. Whether to use a yarn-covered inner layer structure

- 3. Fixing edge type and installation method

- 4. Operating environment (oil volume, chip volume, movement mode)

- During the design phase, the source of chips, the direction of splashing, and the equipment structure will be evaluated simultaneously to ensure actual protective effect and service life.

- Application Scope

- Flat-Type Rubber Covers are commonly used in:

- 1. Traditional machine tools

- 2. CNC machine tools

- 3. Metal cutting equipment

- 4. Fixed protective areas where metal chips easily accumulate

- Through proper design of rubber flat chip guards, chip accumulation problems can be effectively reduced, maintaining equipment operational stability and extending service life.

- FAQ|Common Issues with Flat-Type Rubber Cover

- Q1: What is the difference between flat-type rubber cover and bellow-type rubber cover?

- A: Flat-type rubber covers are suitable for fixed protection areas and concentrated chip accumulation locations, while bellow-type rubber covers are more suitable for protective applications requiring stretching and variable stroke.

- Q2: Can flat-type rubber covers withstand large amounts of iron filings?

- A: Yes, with appropriate thickness (e.g., 2mm or 3mm) and a mesh-covered structure design, they can withstand large amounts of iron filings splashing and accumulating.

- Q3: When should mesh-covered rubber chip guards be selected?

- A: When the chip guard needs to withstand greater tensile force or be used for extended periods, a mesh-covered structure is recommended to improve tensile strength and durability.

- Q4: Can flat rubber chip guards be customized in size?

- A: Yes, the length, width, and thickness of the chip guards can be customized according to the actual dimensions of the equipment and protection requirements.

- Q5: Are flat rubber chip guards suitable for high-temperature iron filings environments?

- A: Not recommended. Rubber flat chip guards are suitable for processing conditions where the temperature of the metal chips is not too high. For high-temperature environments, it is recommended to choose a metal protection solution.

.png)