Products

- Home

- Products

- Telescopic spring covers

- Telescopic spring covers

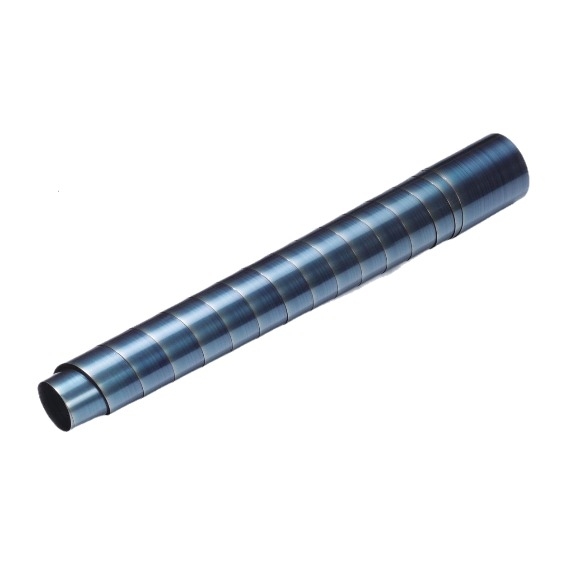

Telescopic spring covers

Telescopic spring covers

- Product Definition and Uses

- Telescopic spring covers are axial transmission protective components made of spring steel. They are primarily used to protect lead screws, ball screws, lathe screws, hydraulic cylinders, pneumatic cylinders, and precision mold bases, among other transmission components. During reciprocating motion, they effectively prevent metal chips, dust, and foreign objects from entering the screw surface, ensuring motion accuracy and extending service life.

- Compared to cloth or rubber bushings, Telescopic spring covers offer significant advantages in environments with abundant metal chips and metal cutting. Because metal chips do not easily adhere to the metal bushing surface, cleaning and maintenance time is effectively reduced, making them particularly suitable for long-distance screw protection and high-load industrial applications.

- When is it appropriate to use a telescopic spring cover?

- In practical machine tool and heavy-duty cutting applications, metal screw inserts are particularly suitable for the following conditions:

- • The screw is exposed to large amounts of iron filings or metal dust for extended periods.

- • Harsh cutting environments where cloth or rubber inserts are easily damaged.

- • Long screw strokes requiring continuous protection over long distances.

- • Equipment with high requirements for positioning and repeatability accuracy.

- • A desire to reduce the frequency of cleaning, lubrication, and maintenance.

- In these operating conditions, metal screw inserts provide stable and durable protection.

- Structural and Material Design Specifications

- The metal screw sleeve is designed with a high-strength spring steel structure and can be selected according to the screw size. Its main features are as follows:

- 1. Sleeve body material: SK5 spring steel sheet

- 2. Structure: Helical spring telescopic structure

- 3. Design characteristics:

- 3-1. High restoring force, not prone to elastic fatigue

- 3-2. Smooth surface, preventing iron filings from adhering

- 3-3. Withstands external impact, protecting the screw body

- 3-4. Smooth telescopic movement, suitable for long-stroke reciprocating motion

- A standardized size reference table is also provided for quick selection of specifications including inner diameter, outer diameter, maximum extension length, and minimum compression length.

- Main advantages of telescopic spring cover

- Effectively prevents iron filings, dust, and debris from entering the screw.

- Maintains the accuracy and stability of the screw's reciprocating motion.

- Possesses excellent impact resistance, is not easily deformed or fatigued.

- Maintains a clean appearance and reduces the safety risks of foreign object entrapment.

- Significantly reduces equipment cleaning, maintenance, and lubrication time.

- Selection support and customization instructions

- Telescopic spring cover can be quickly selected or customized according to equipment requirements, including:

- 1. Screw outer diameter corresponding to insert inner diameter

- 2. Maximum tensile length and minimum compression distance

- 3. Total insert length and effective stroke

- 4. Special application conditions (high speed, long stroke, heavy load)

- Through proper selection, the insert can ensure long-term stable protection without affecting screw movement.

- Application Scope

- Telescopic spring cover are commonly used in:

- 1. Lead screws and ball screws

- 2. Lathe and CNC machine tool screws

- 3. Hydraulic cylinders and pneumatic cylinders

- 4. Precision mold bases and linear drive systems

- 5. Heavy cutting and high-dust machining equipment

- Proper metal screw sleeves effectively prevent screw wear and contamination, maintaining the long-term accuracy and reliability of equipment.

- FAQ | Common Issues with Telescopic spring cover

- Q1: What machining environments are suitable for telescopic spring cover inserts?

- A: Telescopic spring cover are particularly suitable for machining environments with a large amount of metal chips and dust, such as lathes and heavy-duty CNC equipment.

- Q2: What is the difference between telescopic spring cover and round rubber bellow?

- A: Telescopic spring cover have better resistance to metal chips and impact, while round rubber bellow are more suitable for environments with high oil and water sealing requirements.

- Q3: Will telescopic spring covers affect the screw's motion accuracy?

- A: No. When correctly selected, metal screw inserts can extend and retract synchronously with the screw, without affecting positioning and reciprocating accuracy.

- Q4: Are there standard sizes for telescopic spring covers that can be quickly selected?

- A: Yes, telescopic spring covers provide a standardized size chart for quick selection of inner diameter, outer diameter, and stroke range.

- Q5: Why can telescopic spring covers save cleaning and maintenance time?

- A: Because metal chips do not easily adhere to the surface of spring steel, the frequency of cleaning can be significantly reduced, and maintenance time can be shortened.

.jpg)

.png)