Products

- Home

- Products

- Aluminum apron way covers

- Aluminum apron way covers

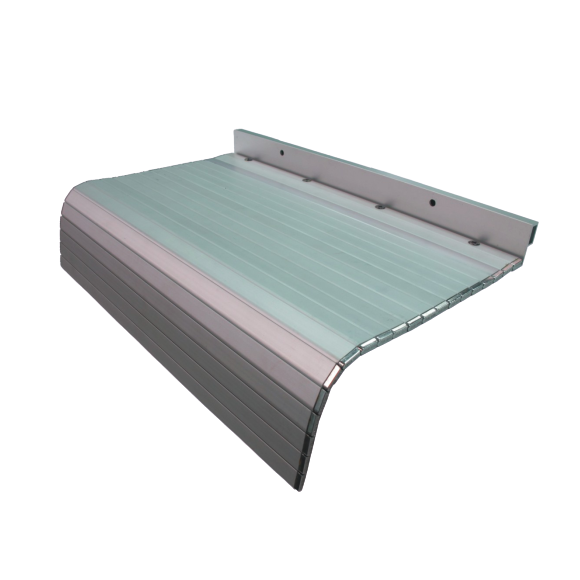

Aluminum apron way covers

Aluminum apron way covers

- Aluminum apron cover product definition and application

- Aluminum apron cover are high-strength equipment protection components assembled from modular aluminum apron cover. Primarily used in machine tools and metal cutting equipment, they effectively block high-temperature iron filings, cutting fragments, and external impacts during operation, protecting slide rails, spindles, and transmission systems. This helps maintain equipment motion accuracy and extends overall service life.

- Compared to fabric or rubber protective structures, aluminum alloy protective roller shutters are more suitable for high-temperature, high-load processing environments with large amounts of iron filings, and are particularly suitable for protecting equipment with long-stroke linear motion. The roller shutter size, fixing method, and stroke can all be customized to meet specific equipment requirements.

- In what situations are aluminum apron cover suitable for use with equipment?

- In practical machine tool and heavy cutting applications, aluminum apron cover are particularly suitable for the following conditions:

- • The machining process generates a large amount of high-temperature iron filings or cutting fragments.

- • The protective structure needs to have high temperature resistance and high impact resistance.

- • The equipment has a long travel range and a large protection area.

- • The protective structure needs to withstand high mechanical loads.

- • General cloth or rubber protective components are not durable enough.

- Under the above conditions, aluminum apron cover can provide stable and long-term protection.

- Main advantages of Megus aluminum apron cover for equipment

- Megus aluminum apron cover is resistant to metal shavings and high temperatures.

- The fixing method, roller shutter width, and length can be customized.

- This product is suitable for long-stroke, high-load applications.

- Customized design and manufacturing capabilities for aluminum apron way covers

- Aluminum apron way covers can be fully customized to meet the specific needs of the customer's equipment, including:

- • Aluminum apron way covers width and effective protection length

- • Equipment travel and installation space configuration

- • Protective strip connection material (rubber or metal)

- • Fixing method and end structure design

- • Expected service life and processing environment conditions

- During the design phase, cutting temperature, chip volume, travel length, and equipment load are simultaneously evaluated to ensure protective effectiveness and long-term stability.

- Application Scope

- Aluminum apron way covers are commonly used in:

- • Various CNC machine tools

- • Traditional and heavy-duty metalworking equipment

- • Long-stroke linear motion equipment

- • High-load automated machining machinery

- Through aluminum apron way covers design, damage to equipment caused by metal shavings and high temperatures can be effectively prevented, maintaining machining accuracy and extending equipment lifespan.

- FAQ|Common Issues Regarding Aluminum apron way covers for Equipment

- Q1: What are the differences between Aluminum apron way covers and fabric apron way covers for equipment?

- A: Aluminum apron way covers offer higher temperature resistance and resistance to metal filings impact, making them particularly suitable for heavy cutting and high-temperature processing environments.

- Q2: Are aluminum apron way covers suitable for long-stroke equipment?

- A: Yes, aluminum apron way covers feature a modular design, making them particularly suitable for protecting equipment with long strokes and high loads.

- Q3: Can aluminum apron way covers be customized in size?

- A: Yes, the width, length, and fixing method of the protective roller shutters can all be customized according to the equipment size and stroke requirements.

- Q4: Can aluminum apron way covers withstand high temperatures and large amounts of metal filings splashing?

- A: Yes, the aluminum apron way covers structure can effectively withstand high temperatures and large amounts of metal filings impact, making it suitable for metal cutting environments.

- Q5: Which equipment is particularly suitable for using aluminum apron way covers?

- A: CNC machine tools and metal cutting equipment that require high temperature resistance, metal filings resistance, and long stroke protection are particularly suitable for using aluminum apron way covers.

.jpg)

.jpg)