Products

- Home

- Products

- Roll-up covers

- Roll-up covers

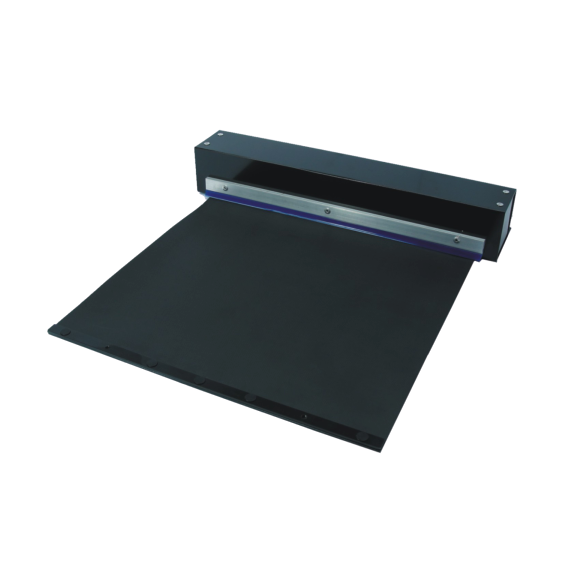

Roll-up covers

Roll-up covers

- Product Definition and Uses

- Equipment roll-up cover are equipment safety components with an automatic rewinding drum structure at their core. They are primarily used during equipment operation to block metal shavings, cutting debris, or external light splashes, preventing operators from being directly exposed to hazardous environments. Simultaneously, they protect critical machine parts and extend equipment lifespan.

- These covers automatically extend and retract with the equipment's stroke, making them particularly suitable for applications with long linear strokes and high-speed movements. They are widely used in traditional lathes, CNC machine tools, woodworking machinery, machining centers, optical instruments, semiconductor equipment, and automated production lines.

- In what situations is it appropriate to use a roll-up cover?

- In practical machine tool and equipment safety applications, roller shutter-type drum covers are particularly suitable for the following conditions:

- 1. Equipment operation generates metal filings, cutting debris, or spatter.

- 2. Long travel distances require coverage of a large protective area.

- 3. High-speed equipment movement necessitates a synchronized and rapid response from the protective structure.

- 4. Close proximity between the operator and the machining area necessitates enhanced personnel safety.

- 5. The requirement for an automatically retractable protective structure when not in operation, saving space. Compared to fixed protective panels, roller shutter-type drum covers offer significant advantages in safety, flexibility, and space efficiency.

- Structural and Material Design Specifications

- Roller shutter-type equipment protective drum covers can be completely customized according to the equipment structure and operating environment. Common components include:

- 1. Drum housing:

- 1-1. General sheet metal (black iron)

- 1-2. Stainless steel

- 1-3. Surface coating or special surface treatment

- 2. Sheet material (selected according to environment):

- 2-1. Rubber sheet (oil-proof, dust-proof)

- 2-2. Steel sheet sheet (resistant to iron filings, high strength)

- 2-3. Aluminum alloy sheet (lightweight applications)

- 3. Structural characteristics:

- 3-1. Automatic rewinding structure, adjustable stretching and retraction speeds

- 3-2. Suitable for high-speed movement (up to 60 m/min)

- 3-3. Design life of over 250,000 cycles

- 3-4. Suitable for long-stroke protection of lightly loaded equipment. In actual selection, a comprehensive evaluation will be conducted based on stroke length, movement speed, environmental medium, and expected lifespan.

- Main advantages of roll up cover

- Customized design and manufacturing capabilities

- Customized roll-up cover can be fully customized to meet the specific needs of your equipment, including:

- • Box width and installation method

- • Total roll length and effective protective stroke

- • Stretching and rewinding speed settings

- • Environmental conditions (iron filings, oil, water, light)

- • Expected service life and operating frequency

- During the design phase, personnel safety, protective effectiveness, and equipment operating efficiency are all considered to ensure reliability in actual use.

- Application Scope

- Roll-up covers are commonly used in:

- 1. Traditional lathes and long-stroke lathes

- 2. CNC machine tools and machining centers

- 3. Woodworking machinery

- 4. Optical instruments and semiconductor equipment

- 5. Automated equipment and production lines

- Through proper roller shutter type protective cover design, industrial safety risks can be effectively reduced while maintaining equipment accuracy and long-term stability.

- FAQ|Common Issues Regarding Roll-Up Cover

- Q1: What is the main function of a customized roll-up cover?

- A: The main function of a customized roll-up cover is to block metal shavings and cutting debris, protecting operator safety and maintaining equipment accuracy.

- Q2: Is a roll-up cover for long-stroke equipment?

- A: Yes, it is. Roll-up covers are particularly suitable for long-distance linear strokes and can automatically extend and retract with the movement of the equipment.

- Q3: Can roll-up covers be used in high-speed equipment?

- A: Yes, depending on the structural design, roll-up covers can support high-speed motion requirements of up to approximately 60 m/min.

- Q4: Can the material of a roll-up cover be customized?

- A: Yes, the material of the drum housing and drum cover can be customized according to the operating environment, such as the presence of metal shavings, oil, water, or light.

- Q5: What types of equipment are roll-up covers suitable for?

- A: Rroll-up covers are commonly used in traditional lathes, CNC machine tools, optical instruments, semiconductor equipment and automation equipment.

(1).jpg)

(1).jpg)