Products

- Home

- Products

- Bellows way covers

- U-type bellows way covers

Bellows way covers

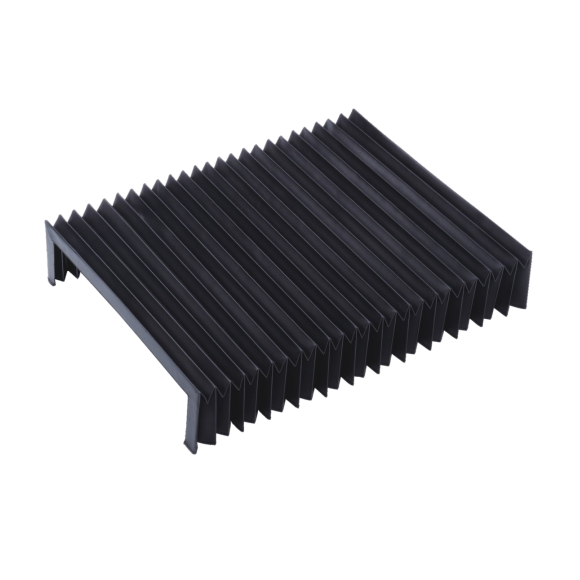

U-type bellows way covers

- Full Top-and-Side Protection for Precision Linear Motion Systems

- U-type bellows way covers are engineered protective components designed for linear motion systems that require multi-sided coverage.

- Unlike flat or single-plane covers, the U-shaped structure protects both the top and sides of guideways, effectively blocking dust, cutting chips, oil mist, and liquids from entering critical motion components.

- This design helps maintain positioning accuracy, reduce wear on guide rails, and extend machine service life, making it a preferred solution for high-precision and high-contamination environments.

- When Is a U-Type Bellows Cover the Right Choice?

- A U-type bellows cover is especially suitable when:

- 1. Linear motion requires top and side protection simultaneously

- 2. Large amounts of dust, chips, or coolant are generated

- 3. The machine structure is wide and single-plane protection is insufficient

- 4. Equipment operates in gantry, planar, or horizontal layouts

- 5. Guideway accuracy and long-term reliability are critical

- Compared to straight bellows covers, the U-type design provides significantly more comprehensive protection, particularly in medium-to-high contamination or multi-directional chip environments.

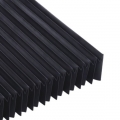

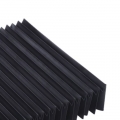

- Engineering Structure & Material Options

- U-type bellows covers are fully customizable based on machine layout and operating conditions.

- Typical construction includes:

- 1. Bellows body: Rubber, plastic, or coated technical fabric

- 2. Front & rear mounting flanges: Sheet metal (steel or stainless steel)

- 3. Optional internal supports:

- 3-1. Rollers (reduced motion resistance)

- 3-2. Steel scissor clip supports (long stroke stability)

- 3-3. Support plates or limitation structures

- Material and structure are selected based on:

- 1. Oil mist / coolant exposure → oil- and water-resistant materials

- 2. PCB or semiconductor equipment → antistatic, low particle emission

- 3. Outdoor or strong light exposure → UV- and weather-resistant designs

- 4. High-temperature processes → materials rated for required temperatures

- Key Advantages

- 1. Full top and side guideway protection—beyond flat designs

- 2. Configurable dustproof, waterproof, oil-resistant, and chemical-resistant properties

- 3. Options for antistatic, UV-resistant, high-temperature, or cleanroom use

- 4. Optimized compression ratios and support structures for stroke and speed

- 5. Designed for long-term stability, accuracy retention, and reduced maintenance

- Custom Design & Application Engineering

- Each U-type bellows cover is engineered to match the actual machine:

- 1. Installation dimensions and mounting method

- 2. Compressed length and maximum stroke

- 3. Operating environment (chips, liquids, temperature, static control)

- 4. Expected service life and motion frequency

- During the design phase, machine structure, stroke length, speed, and contamination type are evaluated to ensure the most suitable material and internal support configuration—avoiding over-design or premature failure.

- Typical Applications

- 1. CNC machine tools and conventional machine tools

- 2. Gantry surface grinders

- 3. PCB forming and drilling machines

- 4. Waterjet cutting machines

- 5. Woodworking engraving machines

- 6. Semiconductor and electronic equipment guideway protection

- A properly engineered U-type bellows cover prevents contamination of guideways, preserves accuracy, and significantly extends machine service life.

- FAQ|Common Questions about U-Shaped Bellows Covers

- Q1: U-type vs. flat bellows—what's the difference?

- U-type covers protect both top and sides, offering more complete protection for wide or heavily contaminated guideways. Flat covers protect mainly one plane and suit cleaner environments.

- Q2: What machines benefit most from U-type covers?

- Gantry machines, CNC machine tools, PCB equipment, waterjet systems, woodworking machines, and semiconductor automation—especially when contamination comes from multiple directions.

- Q3: Are internal supports always required?

- Not always. Short strokes and low speeds may not need support. Longer strokes or wider covers benefit from rollers or steel scissor clip supports for stability and lifespan.

- Q4: How is material selected?

- Based on contamination type, oil/coolant presence, temperature, static control, and cleanliness requirements.

- Q5: What affects service life the most?

- Stroke length, speed, contamination level, material choice, and whether compression ratio and support structures are correctly designed.

.png)