Products

- Home

- Products

- Bellows way covers

- Flat type bellows way covers

Bellows way covers

Flat type bellows way covers

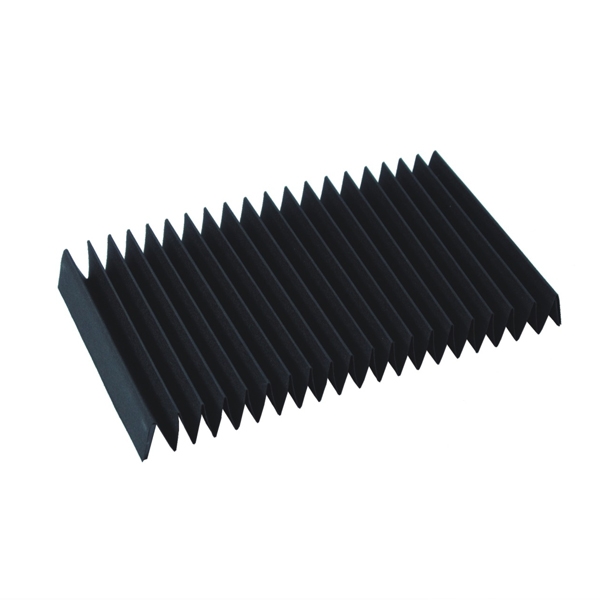

- What is a Flat Type Bellows Way Cover?

- A Flat Type Bellows Way Cover is a high-precision protective solution engineered to shield linear slides, guide rails, and transmission components. By effectively sealing out dust, oil mist, and cutting fluids, it preserves machine accuracy and prevents premature wear in sensitive industrial environments.

- It is particularly essential for Measurement Systems, Semiconductor Tools, and CNC Machine Slideways where maintaining a clean operational environment is a critical performance factor.

- Engineering Focus: Solving Design Challenges

- Precision Stroke Management: Designed with optimized compression ratios to provide maximum travel while occupying minimal retracted space.

- Environment-Specific Materials: From Anti-static (ESD) fabrics for semiconductor fab tools to Oil-resistant & UV-resistant coatings for outdoor or machining applications.

- Thermal & Chemical Stability: Available in heat-resistant materials that withstand consistent exposure to high temperatures and aggressive coolants.

- Low-Friction Operation: Smooth extension and retraction mechanics reduce drag, ensuring your linear motors or drive systems maintain peak efficiency.

- Accelerate Your Design with Expert Protection

- Choosing a bellows way cover isn't just about dimensions; it’s about environmental compatibility. Our semi-automated technical system ensures you get the data you need without the wait.

- 1. Rapid Technical Response: Receive your quote and material recommendations within 24 hours to keep your project on schedule.

- 2. Design Constraint Collaboration: Dealing with a narrow installation space or high-speed stroke? Our engineers will review your layout to ensure zero-interference operation.

- 3. Tailored Material Selection: We assist you in selecting the right base—from rubber-coated fabrics to specialized polymers—ensuring long-term stability and cost-effectiveness.

- FAQ | Common Issues with Flat-type bellows covers

- Q: How do I choose the right material for my Bellows cover?

- A: Material selection depends on your "Processing Atmosphere." For dry dust, standard fabrics suffice; for semiconductor tools, we recommend Anti-static materials; for heavy coolant exposure, we provide Oil-proof coated base fabrics.

- Q: Does operating speed affect the life of a Flat Bellows?

- A: Yes. For high-speed applications, we integrate internal support structures like travel limiters or rollers to prevent "whiplash" effects and ensure smooth motion.

- Q: Can these be customized for vertical installations?

- A: Absolutely. We adjust the internal support and mounting flange design to prevent sagging in vertical or ceiling-mounted configurations.

*For a rapid quote, please include: Max. Extension & Min. Compression, Internal/External Width, Operating Environment.*

.png)