Products

- Home

- Products

- Machine brushes

- Metal channel strip brushes

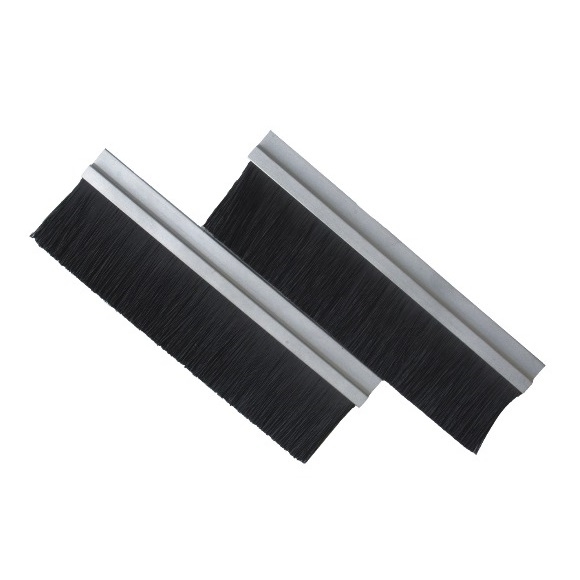

Metal channel strip brushes

Metal channel strip brushes

- Product Definition and Uses

- Customized machine brushes are industrial cleaning components specifically designed for the cleaning and maintenance of machine tools, primarily used in CNC milling machines, machining centers, and various other machine tools. Their main function is to clean chips, dust, and residue from machine table surfaces, linear guides, and the area around the tool magazine after equipment operation or processing, maintaining smooth equipment operation, machining accuracy, and an overall clean environment.

- The cross-sectional specifications of the brushes (U5, U5 Special, U8), bristle material, bristle diameter, and bristle length can all be customized to meet specific usage requirements. For special sizes or applications, custom orders can be made after quantity confirmation, suitable for various non-standard equipment or special cleaning locations.

- When is it appropriate to use a customized machine brush?

- In actual machining and equipment maintenance, customized machine brushes are particularly suitable for the following scenarios:

- 1. Chips easily accumulate on machine tabletops, slide rails, or around tool magazines.

- 2. Cleaning is required without damaging guide rails or precision surfaces.

- 3. Cleaning space is limited, and standard brush sizes are not applicable.

- 4. The machining environment requires anti-static or conductive properties.

- 5. It is desirable to adjust the bristle hardness according to cleaning power requirements.

- Compared to disposable cleaning methods, Customized machine brushes can be permanently fixed to the equipment, improving cleaning efficiency and reducing the burden of manual maintenance.

- Structural and Material Design Specifications

- Customized machine brushes can be fully selected and designed according to equipment structure and cleaning needs. Their main structure and materials are as follows:

- 1. Mounting Base: Aluminum Alloy

- 1-1. Lightweight and Corrosion-Resistant

- 1-2. Easy to fix to equipment structure

- 2. Brush Bristle Material (Selected according to requirements):

- 2-1. Nylon 66 Bristle (General Purpose, Wear-Resistant)

- 2-2. Antistatic Bristle (Non-Surface Coating, Long-Term Stability)

- 2-3. Conductive Fiber Bristle (Suitable for ESD Environments)

- 3. Adjustable Bristle Specifications:

- 3-1. Bristle Diameter (Adjustment of Hardness)

- 3-2. Bristle Length (According to Cleaning Depth Requirements) Cross-sectional specifications include U5, U5 Special Type, and U8, which can accommodate different mounting slot types.

- Main advantages of customized machinery brushes

- Various bristle materials are available to suit cleaning or guiding applications.

- The softness and hardness can be adjusted by the bristle diameter to prevent product damage.

- Both the brush body and bristle length are fully customizable.

- Effectively improves the smoothness of automated production line operation.

- Suitable for equipment operating continuously for extended periods.

- Customized design and selection support

- Customized machine brushes can be fully planned according to the customer's equipment conditions, including:

- 1. Cross-sectional specifications (U5/U5 Special/U8)

- 2. Total brush length and effective bristle length

- 3. Bristle material and wire diameter selection

- 4. Installation location and fixing method

- 5. Whether antistatic or conductive functions are required

- During the selection phase, the cleaning object (chips, dust), contact surface material, and operating frequency will be evaluated simultaneously to ensure cleaning effect and service life.

- Application Scope

- Customized machine brushes are commonly used in:

- 1. CNC milling machines

- 2. Machining centers (MC)

- 3. Various machine tools

- 4. Cleaning of worktables, linear guideways, and tool magazine areas

- By configuring appropriate customized mechanical brushes, equipment cleanliness can be effectively maintained, reducing the impact of foreign objects on machining accuracy and improving overall operational stability.

- FAQ|Common Questions about Customized Machine Brushes

- Q1: What is the difference between custom-made mechanical brushes and regular cleaning brushes?

- A: Custom-made mechanical brushes can be designed to fit the equipment structure, installation method, and cleaning needs, making them suitable for long-term fixed use on machines.

- Q2: How to choose the right bristle material?

- A: Nylon 66 is suitable for general cleaning; if there are static electricity issues, it is recommended to choose anti-static or conductive fiber bristles.

- Q3: Can the bristle stiffness be adjusted?

- A: Yes, the stiffness of the bristles can be adjusted by selecting different bristle diameters.

- Q4: Can custom-made mechanical brushes be made in non-standard sizes?

- A: Yes, as long as you provide the dimensions and requirements, custom-made brushes can be made after confirming the quantity.

- Q5: Which equipment is particularly suitable for using custom-made mechanical brushes?

- A: CNC milling machines, machining centers, and machine tools that require regular cleaning of their worktables or slides are particularly suitable for using custom-made mechanical brushes.

(2).png)