Products

- Home

- Products

- Bellows way covers

- Stainless steel-clad bellows way covers

Bellows way covers

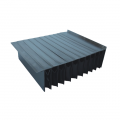

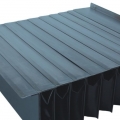

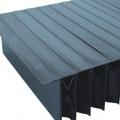

Stainless steel-clad bellows way covers

- Product Definition and Uses

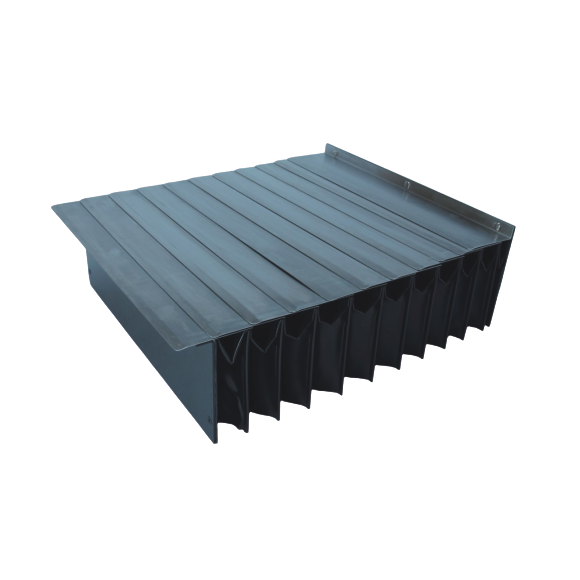

- Bellows Cover with Stainless steel clads are high-strength mechanical protective components specifically designed for heavy cutting, high-temperature machining, and environments with large amounts of metal chips. They are primarily used to protect linear guideways and transmission mechanisms, preventing high-temperature iron filings, metal fragments, or cutting sparks from directly impacting the guideway surface, thus affecting equipment accuracy and lifespan.

- Through a layered, overlapping stainless steel clad structure, these dust covers can withstand high temperatures and mechanical impacts during equipment operation, while maintaining the stability of the guideway movement. They are widely used in heavy cutting processes in CNC machine tools, high-temperature machining equipment, and high-load linear guideway systems.

- When is it appropriate to use a bellows cover with stainless steel clad?

- In practical engineering applications, bellows cover with stainless steel clads are particularly suitable for the following conditions:

- 1. The machining process generates a large amount of high-temperature iron filings or metal cutting fragments.

- 2. The cutting speed is high and the cutting depth is large, constituting a heavy cutting condition.

- 3. The guide rails are exposed to high temperatures or spark spray for extended periods.

- 4. Ordinary cloth or rubber/plastic dust covers are insufficiently durable.

- 5. The equipment has high requirements for precision, stability, and service life.

- Compared to ordinary dust covers, bellows cover with stainless steel clad a higher level of heat resistance and impact protection.

- Structural and Material Design Specifications

- Bellows cover with stainless steel clads can be fully customized to fit the equipment structure and operating conditions. Common components include:

- • Outer protective structure: Stainless steel fish-scale sheets (overlapping metal sheets)

- • Inner layer of the dust cover body: Rubber/plastic leather or heat-resistant base material

- • Front and rear mounting flanges: Sheet metal (steel or stainless steel)

- • Internal support structure (optional):

- o Rollers (reduces movement resistance under high loads)

- o Steel scissor clamps (support long strokes and weight)

- o Support plates or stroke limiting structures (maintain folding stability) In actual design, the following factors will be comprehensively evaluated:

- • Cutting temperature and spark quantity

- • Metal chip size and impact direction

- • Slide rail travel length and movement speed

- • Equipment operating frequency and expected lifespan

- Main advantages of bellows cover with stainless steel clad

- Effectively blocks high-temperature iron filings, metal fragments, and cutting sparks.

- The stainless steel fish-scale structure provides excellent heat resistance and impact resistance.

- Can be customized with an inner dustproof material to provide dustproof, waterproof, and oil-proof functions.

- Suitable for linear guideways and high-load linear motion systems.

- Supports complete customized design to meet different equipment sizes, stroke, and lifespan requirements.

- Customized design and manufacturing capabilities

- Bellows cover with stainless steel clads can be fully customized to meet specific customer equipment requirements, including:

- • Installation dimensions and fixing method

- • Compression length and maximum extension stroke

- • Stainless steel clads material, thickness, and arrangement

- • Environmental conditions (high temperature, cutting chips, oil mist)

- • Expected service life and operating frequency

- During the design phase, we comprehensively evaluate processing conditions, slide rail type, and protection level requirements to assist customers in selecting the most suitable structural configuration to ensure effective protection and long-term stability.

- Application Scope

- Bellows cover with stainless steel clads are commonly used in:

- • Traditional machine tools and various CNC machine tools (heavy cutting)

- • Linear guideway protection for CNC machine tools

- • PCB forming machines and PCB drilling machines

- • Waterjet cutting machines

- • Wood carving machines and high-load processing equipment

- Through the protection of bellows cover with stainless steel clads, high-temperature metal chips can be effectively prevented from entering the guideway system, reducing the risk of wear and tear, and maintaining the accuracy and service life of the equipment.

- FAQ | Common Issues with Bellows Cover with Stainless Steel clads

- Q1: When is it necessary to use a bellows cover with stainless steel clad?

- A: When equipment undergoes heavy cutting or high-temperature processing, generating a large amount of hot iron filings or metal fragments, a bellows cover with stainless steel clad is usually necessary.

- Regular cloth or rubber/plastic dust covers are easily damaged quickly in such environments.

- Q2: What is the difference between a bellows cover with stainless steel clad and a regular dust cover?

- A: Bellows cover with stainless steel clads have higher heat resistance and impact resistance, making them particularly suitable for high-temperature and heavy cutting environments. Regular dust covers are mostly used in dusty or low-temperature processing applications.

- Q3: Will a bellows cover with stainless steel clads affect the smoothness of slide rail movement?

- A: With proper design, a bellows cover with stainless steel clad can maintain the stability and smoothness of slide rail movement even at a high protection level. It is usually paired with rollers or scissor clamp structures to reduce movement resistance.

- Q4: Can bellows cover with stainless steel clad be customized?

- A: Yes, bellows cover with stainless steel clads can be fully customized to meet specific equipment dimensions, stroke length, cutting conditions, and service life requirements.

- Q5: What factors affect the service life of bellows cover with stainless steel clads?

- A: Service life is mainly affected by cutting temperature, metal chip impact strength, slide rail stroke, movement speed, and structural design. Proper fish-scale thickness and support structure configuration can effectively extend the actual service life.

.png)

.png)

.jpg)